Generator Preventative Maintenance in Colorado

One of the more common questions we get is, “What items are included in your preventative maintenance service programs?” Below, you will find a breakdown of what items our technicians cover and their frequency, but keep in mind we can custom-tailor our generator preventative maintenance for your equipment or application.

Recommended Generator Maintenance Schedule:

Major “A” Service (1 Time per Year)

Minor “B” Service (1 Time per Year)

Belts and Hoses (once every 3 years)

Load Bank and Transfer Testing (once every 3 years or if needed)

Fuel, Oil, and Coolant Testing (1 Time per Year)

Major “A” (Full) Generator Service

- Complete Oil and Filter Change

- Change fuel filters

- Inspect Air Filter*

- Inspect & adjust fan belts

- Check battery level & maintain battery test report

- Check operation of battery charging equipment

- Inspect electrical connections in gen

- Inspect spark plugs and wires*

- Check exhaust system to be clean and free of leaks

- Operate generator and check for correct voltage and frequency

- Clean debris in and around unit and controls

- Inspect unit for wet stacking

- Operational check of generator set

- Operational Check of ATS

- Topping off fluids

- Detailed Inspection of generator

- PM report

First, all fluid filters will be changed on the engine, and the oil will be replaced. Your generator will then be tested for proper operation. Finally, all metering will be checked for proper operation, and safeties will be tested and verified. You will receive a copy of our PM report and any recommendations or notes from the technician.

*Replacement parts extra

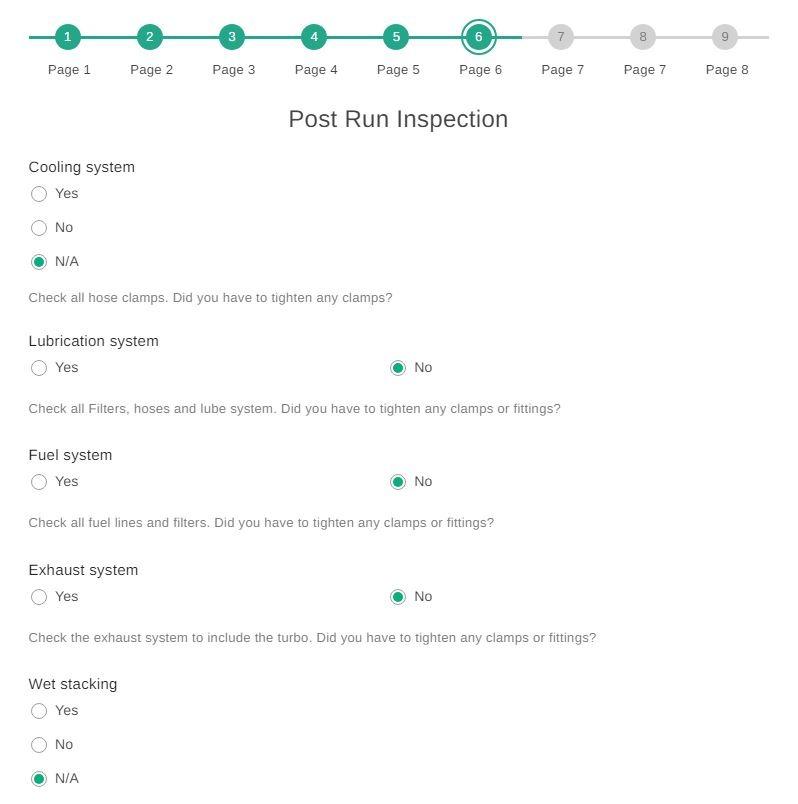

Minor “B” Generator Inspection

- Inspect Air Filter*

- Inspect & adjust fan belts

- Check battery level & maintain battery test report

- Check operation of battery charging equipment

- Inspect electrical connections in gen

- Inspect spark plugs and wires*

- Check exhaust system to be clean and free of leaks

- Operate generator and check for correct voltage and frequency

- Clean debris in and around unit and controls

- Inspect unit for wet stacking

- Operational check of generator set

- Operational Check of ATS

- Topping off fluids

- Detailed Inspection of generator

- PM report

Please note that the specific maintenance requirements for your generator and transfer switch may vary, and replacement parts are an additional cost above the items we use during preventative maintenance services.

*Replacement parts extra

Annual Preventative Maintenance Contracts

Since most manufacturers recommend servicing your generator at least once per year, Colorado Standby offers annual preventative maintenance contracts. Call or Chat with us to learn more!

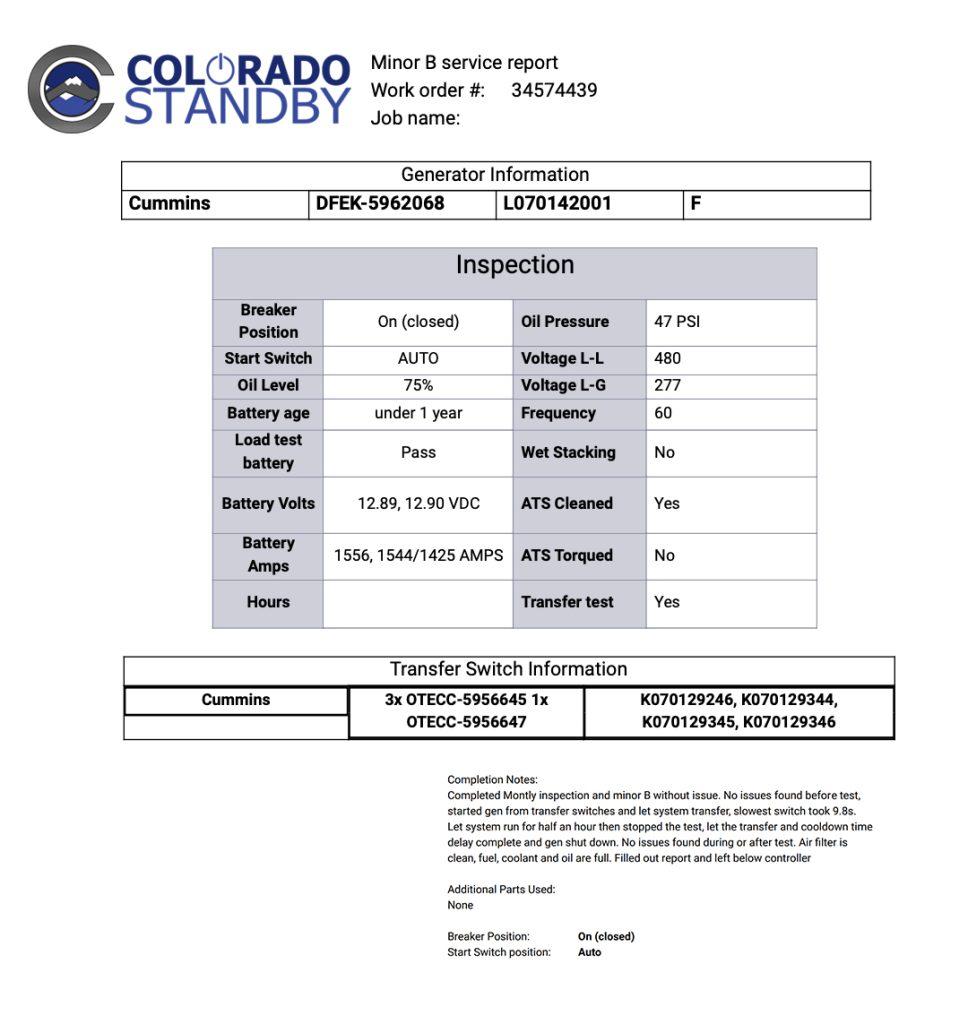

Generator Belts and Hoses Service (PM)

- Belts and hoses replaced

- Cooling system fluid swap and inspection

- Lab analysis on coolant samples

The belts and hoses of your generator do not have to be replaced yearly, but they do need to be inspected for premature wear or damage. In addition, we do recommend replacing belts and hoses at least every three years. These components can get brittle and crack over time, potentially causing coolant leaks or improper cooling. If a belt breaks during operation, overheating can occur and potentially damage the engine.

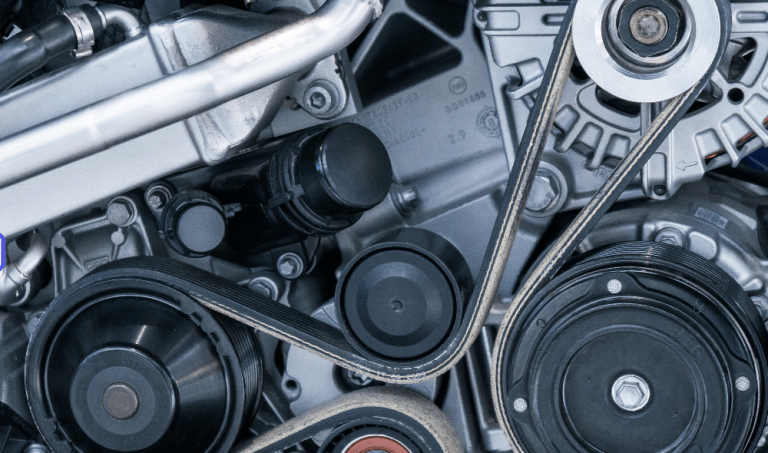

Load Bank Test

Periodically conducting load bank tests, which simulate the generator providing power for a building at near full load, is important to ensure its operation and performance. This tests the full capability of the generator, and it helps identify any potential issues while ensuring the generator can handle the expected electrical load during an outage. We have the equipment to perform these tests and make sure the “real world” performance of your generator is verified.

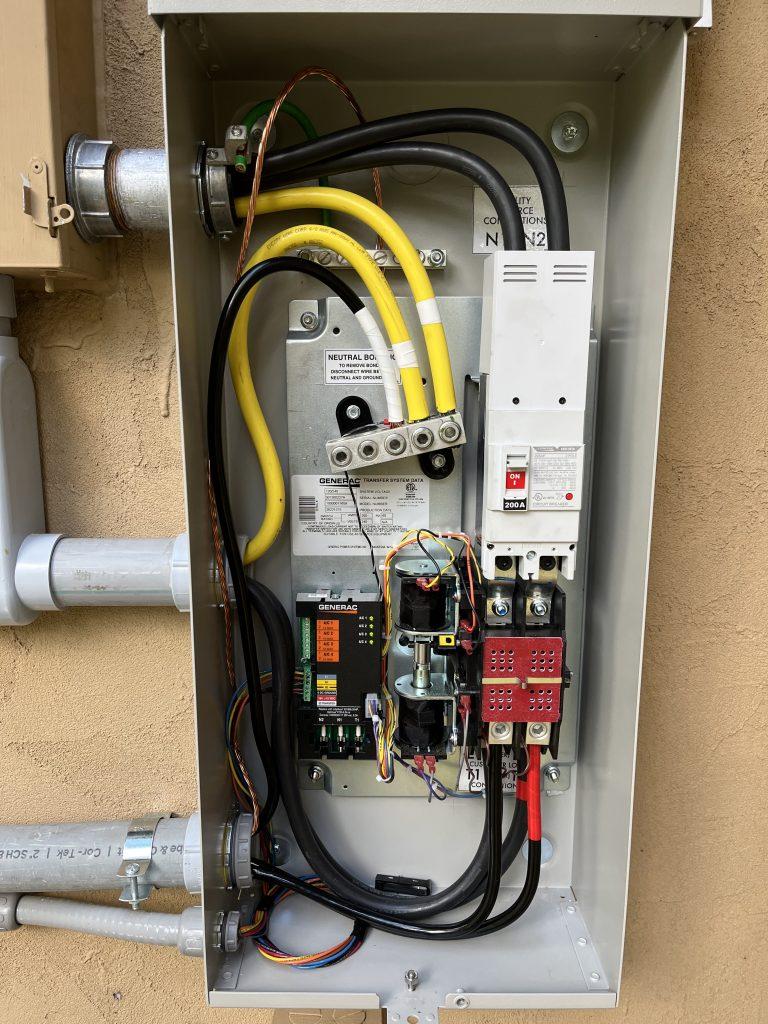

Transfer Test

A generator transfer test, also known as a transfer switch test or a generator transfer panel test, is a procedure performed to verify the proper functioning of a generator’s transfer switch or transfer panel. Because we perform transfer tests at every Major A service and Minor B service unless the customer declines. This is one of the most critical components to test because your generator can run perfectly, but if the transfer switch doesn’t “transfer,” you will never be able to use your backup power.

Fuel, Oil, and Coolant Testing

Fuel, oil, and coolant testing for generators involves analyzing samples of these fluids to assess their quality, condition, and suitability for optimal generator performance. Regular testing helps identify potential issues or contaminants that can affect the generator’s operation and reliability.

Contact Our Service Department

If you are looking for a professional generator maintenance company that you can depend on, email us directly at [email protected] with any questions you may have.

If you prefer to speak to someone immediately, you can give us a call toll free at 866-888-6111 option 3.